Transforming the Mining Industry Through Intelligence and Automation

With over 30 years of mining expertise, we're building the future of mining operations through cutting-edge software, data analytics, and machine learning.

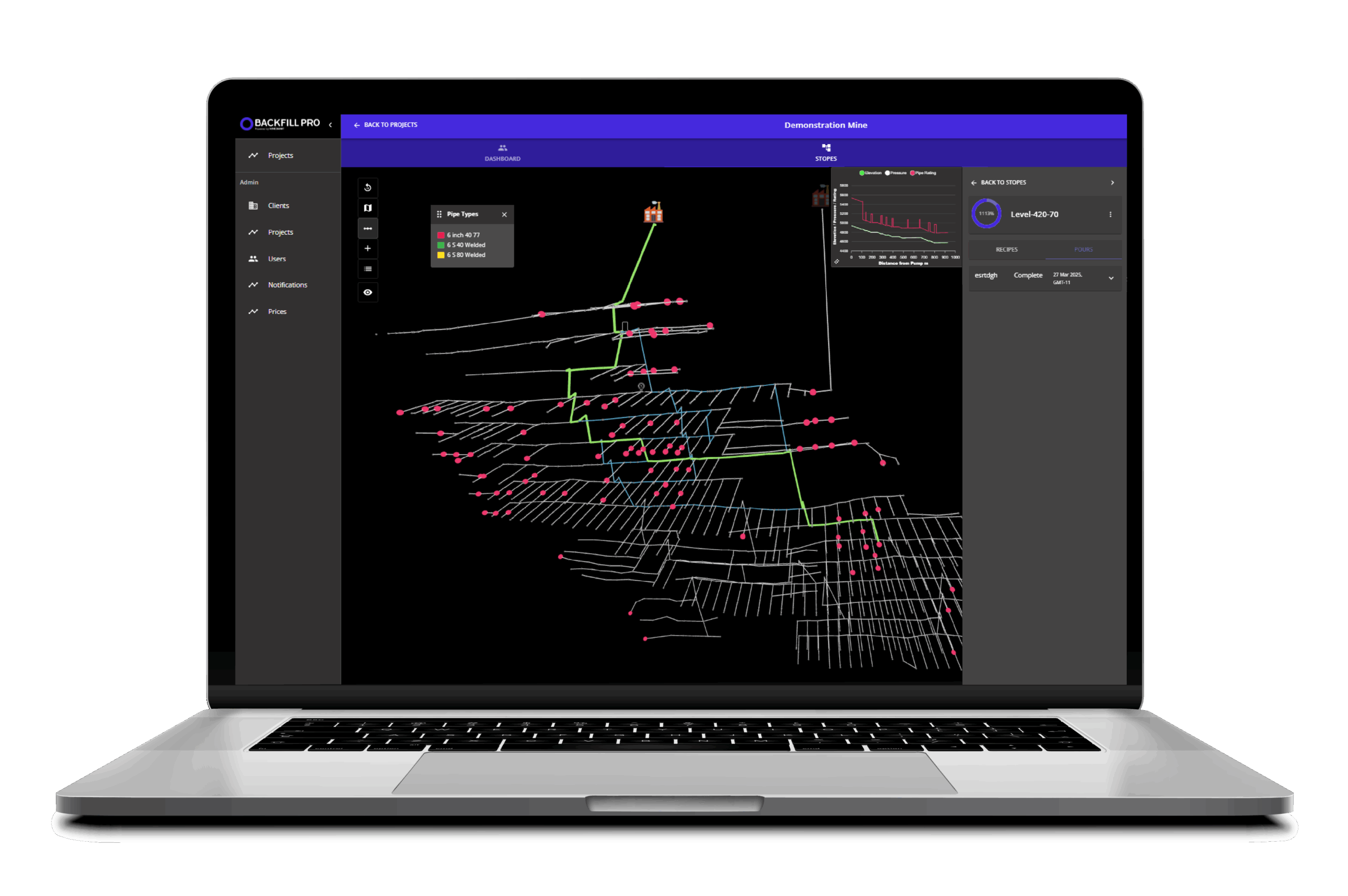

Advanced backfill management and optimisation software for safer, more efficient backfilling operations.

-

Backfill Pour Planning

Hydraulic modelling of every stope to determine expected operating pressures within the reticulation system.

-

Binder Optimisation & Planning

Generate stope-specific backfill recipes that meet strength requirements while optimising binder usage and delivery schedules.

-

Data Management

Centralise all backfill related information, drawings, test results and operational data in a single database for easy access and control.

-

Record Keeping

Offers historian functionality, preserving process and material records for each pour to support traceability and reconciliation.

-

Accountability

Integrates an approval workflow for mix design changes, pour authorisations, and operational sign-off to ensure compliance and process integrity.

-

Performance Tracking

Provides real-time dashboards to monitor key performance indicators and system performance.

Expansion Modules

-

QA/QC Data Capture, Management & Analysis

Consolidate QA/QC data in one place to track binder performance, strength design curves, material variability and strength development trends.

-

Wear Monitoring & Predictive Maintenance Scheduling

Monitor system throughput and wear spool data to optimise maintenance schedules and replace piping before it fails.

-

Editor Tools

Incorporates hydraulic and operational modelling tools to evaluate future system expansions, modifications, or optimisation scenarios.

Trusted by Mining Engineers

“Backfill Pro software has been a great asset for Leeville Mine helping analyse our hydraulic and paste rheology. With the Backfill Pro software, we have been able to look at expected pressures in our boreholes, percentage solids, percentage cement binder, and select the most optimal paste recipes. Overall, it is a software that adds a lot of value to our operation and one that we depend on to successfully optimise our paste pours.”

Jose, Nevada Gold